Manufacturing Process

At Plati, Jewelry manufacturing is the process of creating finished Jewelry pieces from raw materials. It is a complex and multi-step process that involves several stages, including design, prototyping, casting, finishing, and setting. The entire process encompasses specialised knowledge, equipment, and materials. It is typically done under the experienced eyes of professionals, such as Jewelry designers, goldsmiths, and technicians. Hence, we thought of sharing an insight into the same:

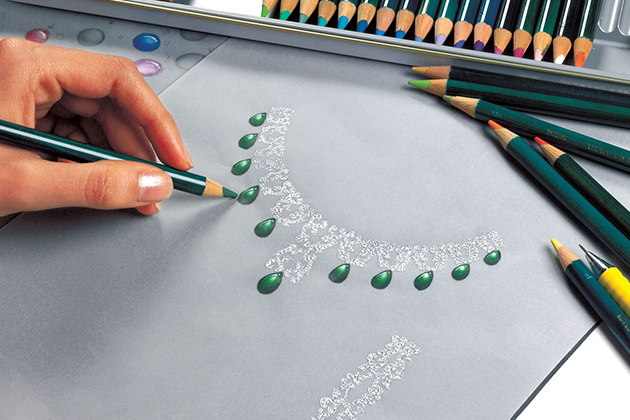

Designing

Designing Jewelry is a crucial aspect of Plati. It involves creating unique and creative designs for jewelry pieces that are attractive to customers and reflect the brand’s vision and mission.

As a jewelry brand Plati has an in-house design house to create our collections. Our design process involves sketches, prototypes, and computer-aided design (CAD) software to bring the designs to life. The final designs have to be functional, aesthetically pleasing, and in line with the brand’s image, and being considerate about factors such as market trends, customer preferences, and the brand’s position.

Production Methods

Each design we make needs a different approach to attain the basic structure of a piece of jewelry. Before analysing the production procedure, it is necessary to get familiar with the various methods of jewelry production. These methods can be defined as the various jewelry manufacturing terms mentioned below :

Handmade

Handmade jewelry production involves various methods, including metalwork, beading, wirework, casting, engraving, and stone setting. Each of these techniques requires a high level of skill and attention to detail, resulting in unique and intricate designs that cannot be replicated by machine-made jewelry . Handmade jewelry is often valued for its quality, uniqueness, and artistry.

Casting

Casting is often used to create intricate and detailed jewelry pieces, as the mould can capture fine details and textures that may be difficult to achieve by hand. It is also a cost-effective method of production for larger quantities of the same design.

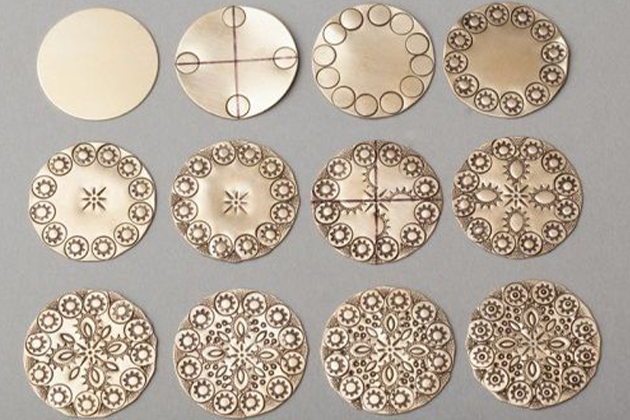

Die Struck

Die striking is a popular production method used in jewelry making, which involves the process of striking a metal blank with a die to create a specific shape or design. Here are the main steps involved in the die striking process for jewelry.

Creation of a metal blank: First, a metal blank is created, typically by rolling a piece of metal into a flat sheet and then cutting it into the desired shape and size.

Preparation of the die: A die is then created with the desired design, typically by carving the design into a piece of metal using a specialised tool called a graver. The die is made in the reverse image of the desired finished product.

Striking the metal blank: The metal blank is then placed on a steel block, and the die is placed on top. A machine is used to strike the die with a large amount of force, pressing the design onto the metal blank and creating the desired shape and texture.

Finishing: The piece is then polished and finished to the desired level, which may include adding additional details or features, such as gemstones or enamel.

Tubing

Tubing involves creating a hollow metal tube, which can then be used to create various types of jewelry, such as bangles, rings, and earrings. Here are the main steps involved in the tubing process for jewelry:

Creation of a metal tube: First, a metal tube is created, typically by rolling a piece of metal into a long, thin strip and then forming it into a tube shape. The metal can be any type of metal used in jewelry making, such as gold, silver, or platinum.

Cutting and shaping the tube: Once the metal tube is created, it can be cut and shaped to the desired length and size. For example, a bangle may be created by cutting the tube to the desired length and then shaping it into a circular shape.

Finishing: The piece is then polished and finished to the desired level, which may include adding additional details or features, such as gemstones or engraving.

Embellishments/ Decorative Process

Embellishments and decorative processes do add a lot of value and uniqueness to a piece of jewelry, and can help to create a one-of-a-kind design that is both beautiful and meaningful.

Finishing

Finishing in the context of jewelry typically refers to the final steps taken to refine and perfect a piece of jewelry. These steps can include polishing, buffing, cleaning, and other surface treatments that give the piece its final appearance and texture.

A well-finished piece of jewelry can make a significant difference in its perceived value and desirability, making it a crucial part of the jewelry-making process.

Plating

Quality Check

Quality check ensures that the final product meets our desired standards of ‘Zero Error’ in design, craftsmanship, and functionality.

The goal of quality control in jewelry design is to catch and correct any issues before the final product is delivered to the customer, ensuring that the jewelry piece meets the desired standards of quality and excellence.

Packaging & Transporting

Packaging and Transportation play a critical role in ensuring that pieces of jewelry arrive at their intended destination safely and securely. Proper packaging and transportation can help to prevent damage, loss, or theft of jewelry items, while also enhancing the overall customer experience.

By taking steps to ensure that jewelry items are packaged and transported safely and securely, we build trust with our customers and ensure the long-term success of our operations.